Leveraging MOSFET Innovations for Advanced Electronics

MOSFETs continue to drive innovation across the electronics industry, playing a critical role in powering modern devices, from automotive systems to home electronics. This article explores various MOSFET model numbers, their manufacturer specifications, parts characteristics, primary applications, and packages, providing procurement professionals, engineers, and industry insiders with essential insights into selecting the right components.

Key Manufacturers

Infineon Technologies: CoolMOS series, Infineon offers high-performance MOSFETs that prioritize energy efficiency and low heat generation, particularly useful in high-frequency applications.

ON Semiconductor: The SuperFET and PowerTrench series from ON Semiconductor are excellent choices for high-speed switching in compact designs, ideal for automotive and industrial applications.

STMicroelectronics: Their STPOWER family, designed for a range of power levels and voltages, offers reliable performance in both AC and DC applications, making it suitable for both industrial and consumer electronics.

Each of these manufacturers provides distinct advantages in MOSFET technology, which can serve as a foundation for various applications.

Key Applications of MOSFETs

Modern MOSFETs serve diverse applications across several industries. Some of the most significant use cases include:

Automotive Industry: MOSFETs are critical in electric vehicles (EVs) and hybrid systems, where they help manage battery power, drive motors, and enhance power efficiency in systems like regenerative braking. High-voltage MOSFETs, such as those from Infineon’s CoolMOS series, provide the power-handling capacity required for these high-stakes applications.

Consumer Electronics: MOSFETs enable precise power control in devices like smartphones, laptops, and home appliances. For example, ON Semiconductor's PowerTrench MOSFETs offer low on-resistance and efficient thermal management, essential for compact devices.

Renewable Energy Systems: In solar power inverters, MOSFETs contribute to the efficient conversion and distribution of DC power. For these applications, high-efficiency MOSFETs with enhanced thermal properties, such as those in STMicroelectronics’ STPOWER series, are preferred for their reliability in outdoor environments.

Industrial Control Systems: MOSFETs are ideal in motor drives, automation equipment, and UPS systems where low-loss power conversion and efficient switching are paramount. The ability of MOSFETs to handle large power loads ensures system stability and minimizes downtime.

These applications demonstrate the versatility and necessity of MOSFETs in various high-tech domains, showcasing the critical role they play in today’s electronic infrastructure.

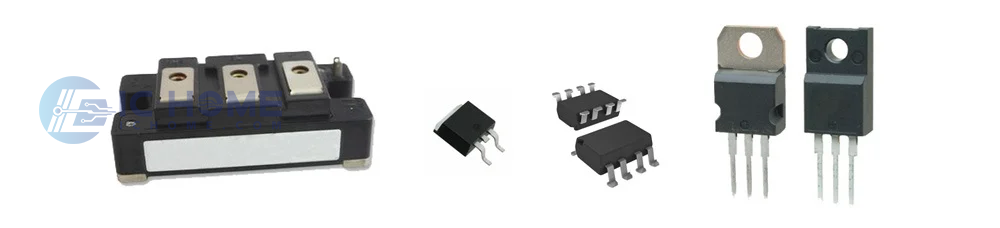

MOSFET Package Types and Selection Criteria

Selecting the correct MOSFET package is essential to achieving the desired performance and efficiency for specific applications. Here’s a breakdown of popular packages and their characteristics:

TO-220 Package: Widely used for power applications, the TO-220 package provides robust thermal handling, which makes it ideal for high-power circuits. The physical structure allows for easy mounting to heat sinks, an essential feature for high-temperature environments.

DFN (Dual Flat No-Lead) Package: Common in compact, high-efficiency designs, the DFN package offers low resistance and excellent thermal dissipation. This package type is favored in applications where board space is limited, such as in smartphones and wearables.

SOT-23 Package: This small-outline package is commonly found in low-power applications where a compact footprint is essential. Its low profile makes it ideal for devices with limited vertical space, including compact consumer electronics.

TO-247 Package: Suited for applications requiring very high power handling, the TO-247 can manage high voltages and currents. Its robust structure and compatibility with heat sinks make it a reliable choice for industrial and automotive systems.

Choosing the right package involves considering thermal management needs, board space constraints, and application-specific requirements. Engineers need to balance these factors to ensure reliability and longevity.

Tips for Engineers and Procurement

To fully leverage the capabilities of MOSFETs, engineers and procurement teams should consider the following tips:

Voltage and Current Ratings: Choose MOSFETs with adequate voltage and current tolerances to match the requirements of your application. Over-specifying can add unnecessary cost, while under-specifying can risk component failure.

Thermal Management: Employ heat sinks or thermal pads when working with MOSFETs in high-power applications. Consider MOSFETs with low on-resistance (RDS(on)) to minimize power dissipation.

Switching Speed: Faster switching MOSFETs reduce energy loss, especially in high-frequency applications like power converters. However, high-speed MOSFETs may require more careful control of gate charge to avoid oscillations.

Packaging Choices: When selecting MOSFET packages, consider board space and thermal dissipation requirements, as well as the need for protective circuitry, particularly in high-voltage designs.

These considerations ensure that the chosen MOSFETs meet the functional, thermal, and durability requirements of their applications.

Conclusion

From automotive to industrial control systems, these components meet the increasing demands for efficient power management and size reduction. By understanding key aspects such as manufacturer specifications, application requirements, and packaging options, engineers and procurement professionals can make informed decisions that optimize their electronic designs. MOSFET technology will likely advance further, providing new opportunities for innovation across diverse electronic sectors.

For more information or to request a quote, please feel free to send us an RFQ.